What price aluminum louver?

What price aluminum louver?

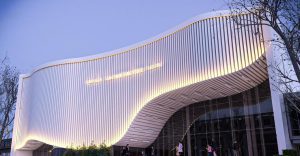

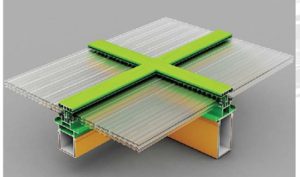

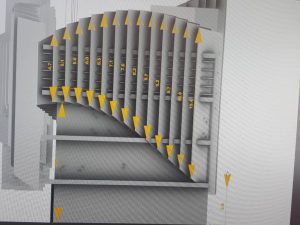

Aluminum louvers are an attractive and functional solution for modern buildings. They are made from aluminum, a lightweight and durable material that is resistant to rust and corrosion. Aluminum louvers come in various styles, shapes, and sizes, and can be customized to fit any building design. They provide excellent ventilation, privacy, and sun protection, making them an ideal choice for both residential and commercial buildings. However, one of the most common questions that people ask about aluminum louvers is their price. In this article, we will discuss the factors that affect the price of aluminum louvers and provide an estimate of their cost.

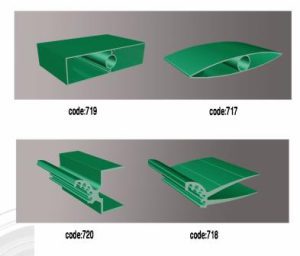

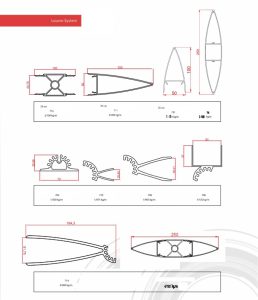

Type of Aluminum Louvers

There are several types of aluminum louvers, including fixed louvers, operable louvers, adjustable louvers, and combination louvers. The type of louver you choose will affect its price. Fixed louvers are the most basic type of louver and are the least expensive. They are a simple, stationary panel that does not move. Operable louvers are more expensive because they can be opened or closed to regulate airflow. Adjustable louvers are also more expensive than fixed louvers because they allow you to control the direction and intensity of airflow. Combination louvers, which combine the features of fixed and operable louvers, are the most expensive.

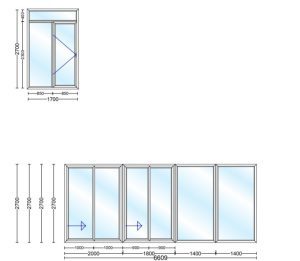

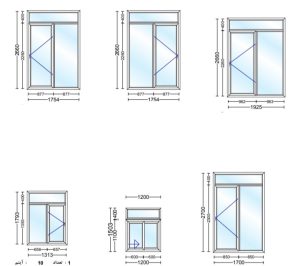

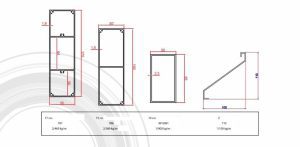

Size of Aluminum Louvers

The size of the aluminum louver is another factor that affects its price. Larger louvers are generally more expensive than smaller ones because they require more material and are more complex to manufacture. The size of the louver also affects the amount of airflow it can provide. Larger louvers provide more ventilation but are also more expensive.

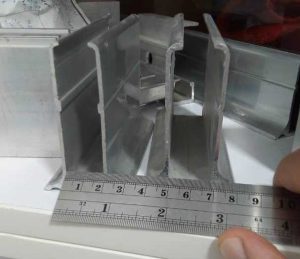

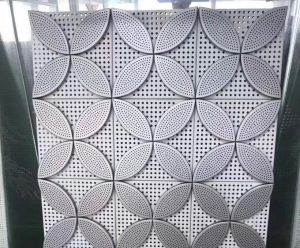

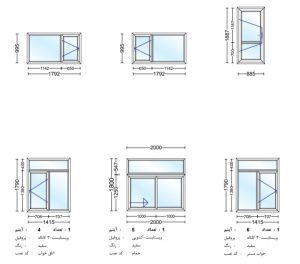

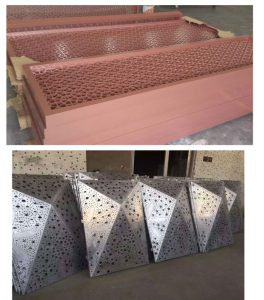

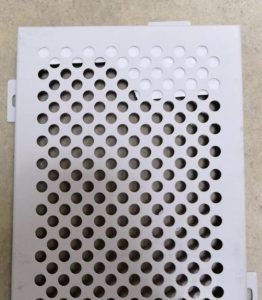

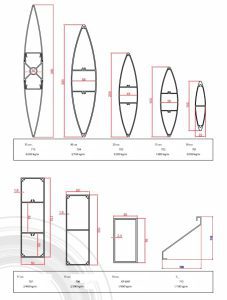

Design of Aluminum Louvers

The design of the aluminum louver can also affect its price. Louvers with complex designs and shapes require more time and effort to manufacture and are therefore more expensive. Louvers with a simple, minimalist design are less expensive than those with intricate patterns or shapes.

Finish of Aluminum Louvers

The finish of the aluminum louver also affects its price. Louvers with a painted finish are generally more expensive than those with an anodized finish. Painted finishes require more labor and materials, which drives up the cost. Anodized finishes, on the other hand, are created through an electrochemical process that changes the surface of the aluminum, making it more resistant to corrosion and wear.

Installation Costs

The installation cost of the aluminum louver is another factor to consider. The installation cost will vary depending on the complexity of the installation and the location of the building. If the building is in a remote area, the installation cost will be higher due to transportation and logistics costs.

Based on the factors above, the price of an aluminum louver can range from $20 to $200 per square foot. However, this is just an estimate, and the actual cost will vary depending on the specific factors discussed above.

To get an accurate estimate of the cost of aluminum louvers, it is best to consult with a professional. A professional installer can assess your needs and provide you with a detailed quote based on your specific requirements. It is also important to consider the long-term costs of aluminum louvers. Although they may be more expensive upfront, they are a durable and low-maintenance solution that can last for decades, providing excellent ventilation and sun protection for your building.

In addition to the factors discussed above, it is also important to consider the quality of the aluminum louver. Lower quality aluminum louvers may be cheaper, but they may not provide the same level of durability and functionality as higher quality louvers. Investing in a high-quality aluminum louver can save you money in the long run by reducing maintenance and replacement costs.

Conclusion

In conclusion, the price of an aluminum louver depends on several factors including the type, size, design, finish, and installation costs. The cost of aluminum louvers can vary widely, ranging from $20 to $200 per square foot, depending on these factors. It is important to consult with a professional installer to get an accurate estimate of the cost of aluminum louvers for your specific project.

Aluminum louvers are an excellent investment for any building. They provide excellent ventilation, privacy, and sun protection, making them an ideal choice for both residential and commercial buildings. They are also durable and low-maintenance, which can save you money in the long run. Aluminum louvers are available in various styles, shapes, and sizes, and can be customized to fit any building design. Whether you are building a new home or renovating an existing building, aluminum louvers can add both functionality and aesthetic appeal.

When choosing aluminum louvers, it is important to consider the quality of the product. High-quality aluminum louvers are more expensive upfront but are a worthwhile investment due to their durability and functionality. Lower quality louvers may be cheaper but may not provide the same level of performance and longevity. It is important to invest in a high-quality aluminum louver to ensure that you get the most value for your money.

In addition to the cost of the louvers themselves, it is also important to consider the installation costs. The installation cost will vary depending on the complexity of the installation and the location of the building. If the building is in a remote area, the installation cost will be higher due to transportation and logistics costs. It is important to factor in the installation costs when budgeting for your aluminum louvers.

Overall, aluminum louvers are a valuable investment for any building. They provide excellent ventilation, privacy, and sun protection, while also adding aesthetic appeal to the building’s design. The cost of aluminum louvers can vary widely depending on the factors discussed above. To get an accurate estimate of the cost of aluminum louvers for your specific project, it is best to consult with a professional installer. With the right investment in high-quality aluminum louvers, you can enjoy the benefits of this durable and functional solution for years to come.